Medium-Density Fiberboard (MDF) has quickly become a go-to material among DIY enthusiasts. Its versatility, affordability, and ease of use make it a trending material, particularly for hobbyists and professionals working on woodworking projects. If you’ve wondered whether MDF is right for your next project, keep reading! This post explores the properties, uses, and benefits of MDF wood, with a data-backed look at why it’s such a popular choice.

What is MDF Wood?

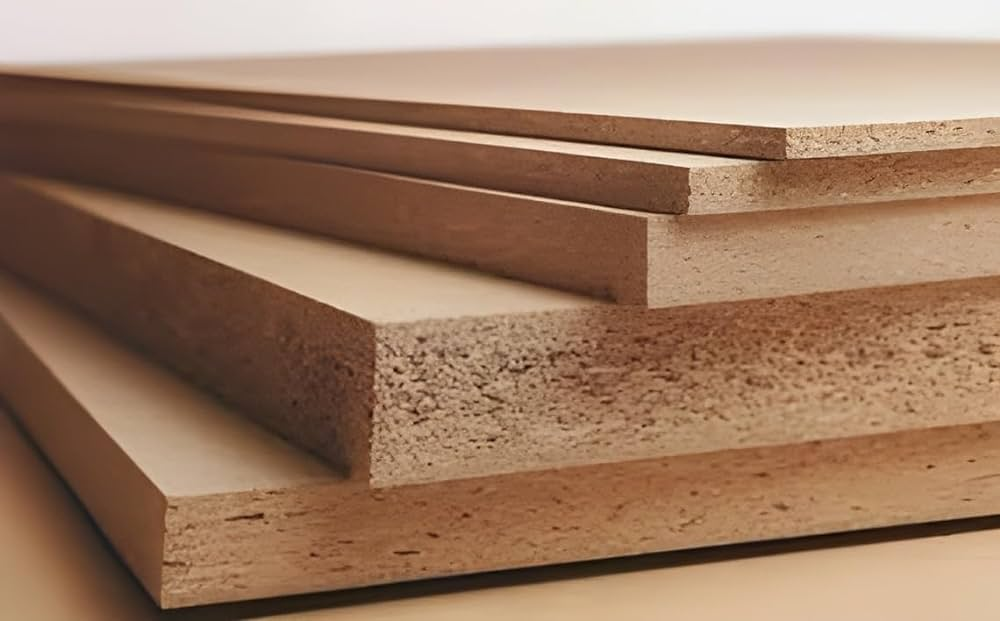

MDF stands for Medium-Density Fiberboard, a type of engineered wood product made from wood fibers compressed with wax and resin under high temperature and pressure. The result is a dense, smooth board that’s perfect for various applications. MDF is distinguished from other types of engineered wood like plywood and particle board by its finer texture and consistent surface, which make it ideal for intricate or painted finishes.

Here’s a quick snapshot of MDF qualities:

- Density: Ranges from 600 to 800 kg/m³, making it sturdier than particle board but less rigid than plywood.

- Thickness: Comes in a variety of thicknesses, from 3mm to 25mm, allowing for versatile use across projects.

- Surface Finish: Its uniform surface requires minimal preparation before paint or veneer application.

According to Allied Market Research, the engineered wood market, including MDF, is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2021 to 2030. This rise in popularity reflects MDF’s versatility and cost advantages.

Key Properties of MDF Wood

- Smooth Surface

MDF’s smooth surface eliminates the need for intricate sanding. It’s naturally ready for paint, veneer, or laminate applications, making it a favorite for decorators and furniture makers.

- Uniform Density

Unlike natural wood, which can have knots and inconsistencies, MDF is homogeneous. This uniform density makes it easier to cut and shape with power tools, reducing the chance of voids or splits.

- Cost Efficiency

MDF is significantly more affordable than natural wood like oak or maple. Its low cost makes it accessible to DIYers and budget-conscious builders.

- Easy Workability

Its softer structure is compatible with basic woodworking tools, making precise cuts and intricate shapes achievable without industrial-size equipment.

Uses of MDF in DIY Projects

MDF is one of the most versatile engineered woods on the market, lending itself to a variety of applications across home improvement and decor. Below are some of its most common uses:

1. Furniture Making

MDF is widely used for creating custom furniture pieces like cabinets, drawer fronts, desks, or shelving units. Its uniform texture ensures a smooth finish, even with detailed designs.

2. Wall Paneling and Wainscoting

DIY enthusiasts often use MDF for decorative wall panels or wainscoting due to its ability to hold paint and its polished look. It’s an economical choice compared to plywood or solid wood panels.

3. Decorative Elements

From crown moldings to intricate laser-cut designs, MDF performs beautifully in decorative elements thanks to its ability to hold fine details.

4. Prototyping

Designers and hobbyists love MDF for creating prototypes of models or structures thanks to its affordability and ease of machining.

5. DIY Art and Crafts

Whether it’s custom signs, picture frame molds, or even dollhouses, MDF proves ideal for crafting projects that need precision cuts and simple decorating.

Why Choose MDF for DIY Projects?

MDF might not have the glamour of solid hardwood, but it comes with a host of distinct advantages that make it perfect for DIY projects. Here are the top reasons people are turning to MDF:

1. Affordability Without Sacrificing Quality

MDF’s competitive cost is one of the primary reasons for its popularity. Despite being cost-efficient, it offers a professional finish indistinguishable from expensive materials when painted or veneered.

2. Ease of Cutting and Shaping

MDF cuts cleanly, meaning it won’t splinter like solid wood or plywood. This allows DIYersAn error occurred during generation. Please try again or contact support if it continues. and professionals to work with more precision, even on intricate designs.

3. Ready for Finishing

With a uniform texture and no knots or voids, MDF requires minimal preparation before painting or veneering. This saves time and effort compared to other materials that may require sanding or filling.

4. Versatility

From furniture making to decorative elements, MDF can be used in a wide range of projects without sacrificing quality or durability.

Conclusion

MDF wood is a game-changer for DIY enthusiasts and professionals alike. Its unique properties make it an ideal choice for various applications, from furniture making to home decor and crafts. With its competitive price, easy workability, and professional finish, it’s no wonder MDF has become the go-to material for many DIY projects. So, the next time you’re looking to start a new project, consider reaching for this versatile and budget-friendly wood option. More information on types of MDF available in the market such as moisture resistant (MR) or fire retardant (FR) would be an interesting addition to this post. Additionally, discussing how MDF compares to other popular materials like plywood or particle board could provide readers with a better understanding of its advantages. Other topics worth exploring could include tips for working with MDF and ideas for incorporating it into various DIY projects.